Navigating the world of machine tool suppliers: a comprehensive overview

Introduction:

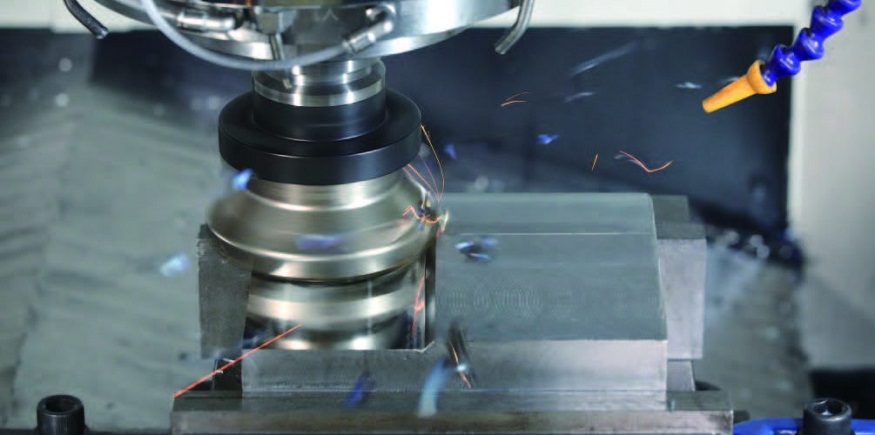

Machine tool suppliers are crucial for the manufacturing area, presenting essential systems and machinery for precision cutting and shaping throughout numerous industries. They play an essential role in enabling the production technique by imparting vital tools and substances for manufacturing. In this article, we delve into the realm of machine tool suppliers, exploring their significance, the types of machinery they provide, key factors to remember when selecting a dealer, and the present-day technologies shaping this sector.

These providers provide a huge range of machinery essential for cutting and shaping products in industries such as cars, aerospace, and construction. From lathes and milling machines to CNC routers and grinders, device equipment is critical for creating particular additives and enhancing production efficiency. Stay tuned as we discover the significance of device suppliers and the evolving trends in this dynamic industry.

Role of machine tool providers

Machine tool suppliers are the inspiration upon which production stands because they offer quite a few systems, which improve production speed and accuracy. The voice is made of numerous suppliers who serve in such sectors as automotive, aerospace, electronics, creation, and so forth. The device suppliers could come in with an extensive type of lathes, milling machines, CNC routers, grinders, and so on, each serving a selected motive inside the production line.

Range of machines from machine tool suppliers

Lathes:

A lathe is a multi-tasking system used for shaping and turning substances consisting of metallic, wooden, and plastic. They are paramount for the manufacture of additives that are usually cylindrical and equally unique.

Milling Machines:

One of the main operations carried out with milling machines is cutting and shaping solid materials. They can be used in different categories: vertical, horizontal, and CNC, all depending on the type of process one needs to attain.

CNC Routers:

CNC routers employ the help of computer numerical control to do scrolling, carving, and engraving. These materials are surface-plated to meet environmental requirements and are extensively utilized in woodwork, the production of signs, and prototyping.

Grinders:

Grinders are used in operations for machining to smooth particular surface finishes of the workpieces that are accurate. They play an elementary role in factories that require tight tolerances and high-quality surfaces.

Crucial factors in the selection of a machine tool supplier

Quality and Reliability:

Find suppliers dealing with top mechanical quality and stable operations. Go through customer reviews and decide for yourself if you can rely on them, and also check their reputation, which shows their history.

Technological Capabilities:

Evaluate the technological in-house strength of the supplier in terms of remote controls, automation, and internet connection aspects.

After-Sales Support:

The trusted supplier gives you a wide range of after-sales support, which entails maintenance services, spare parts availability, and technical support.

Cost and Value Proposition:

Besides the initial cost of machinery, account for running costs such as gas, insurance, and loan fees, and the results in the form of productivity gains and durability.

Dynamically developing machine tool producers

As technology advances at a rapid pace, machine tool suppliers are incorporating digitalization, automation, and smart manufacturing concepts. Industrial 4.0 initiatives are encouraging the succession of sensors and maintenance algorithms on machine tools with data analytics, which leads to proactive maintenance, optimized production schedules, and improved operational efficiency.

The role of innovation for machine tool manufacturers

Advancing Additive Manufacturing:

Among the machine parts manufacturers, the pioneers in the utilization of the most advanced types of additive technology, mainly 3D printing, have to be pointed out This advancement will help create complex shapes or manufacture high-precision prototypes with very little waste generated, due to which we will be able to make our production much more sustainable.

Integrating Robotic Automation:

Machine tool makers, on the one hand, are merging cobots into their product lines to reformat machining processes. These robots not only complement human operators but also boost speed, accuracy, and output. As robots are integrated into automation on the shop floor, there is a streamlining of resources, resulting in overall efficiency.

Developing Hybrid Machining Systems:

The suppliers of machine tools are creating hybrid machining systems that can mix subtractive technology by milling with the additive process of 3D printing. Such hybrid machines take on such enormous versatility that manufacturers can perform numerous operations with the help of one system, to improve workflow processes and shorten overall lead time.

The importance of machine tool manufacturers on the global stage

Enabling Global Trade:

Machine tool manufacturers do global trade by offering technologies that drive performance to the next level. Such easy access accelerates cross-border partnerships, widening the market reach and delivering a strong interconnected supply chain system, contributing to the global economy and globalization.

Driving Job Creation and Skills Development:

Besides offering machines, machine tool suppliers also contribute to job creation and training. They do this by setting up training programs and giving technical support; they enable manufacturers to fully utilize modern machining systems and increase the capabilities of the workforce as well as workers’ income, thus contributing to sustainable economic growth.

Conclusion:

Machine tool suppliers in Saudi Arabia perform a vital task for the country by implementing both ambitious programs for industrial diversification and improved technology. The advancement of technology has led to an increase in the demand for high-tech equipment spanning the oil and gas, automobile, and construction sectors, touching the machine tool industry in the area. To boost the industrial capabilities of their business, selecting the right machine tool supplier that is both reliable and innovative becomes a key component of their strategies.

Lastly, the society of machine tool suppliers in saudi arabia is enormous and complex, to say the least, due to the distinct nature of the modern production process. Regardless of the country, Saudi Arabia, or any other, an enterprise has to concentrate on the supplier of quality machines and also those with technical knowledge who will offer consistent after-sales service for it to fit in well in the competitive market.